OEM Hot-dip Galvanizing Thimble Eye Nut

PRODUCT INTRODUCTION

The thimble eye nut is assembled with the thread end of 1/2 or 5/8 inch eye bolt, which goes across the wooden pole for supporting the strain insulators to the dead end wire, the twin-eye nut is used with double guys.

The main process in making eye nuts is drop forging. The material is steel rod. When the steel rod is heated to red-hot, the red rod will be shaped by a localized compressive force. By using different tooling, it produces the thimble eye nut and oval eye nut. The forged eye nuts are all polished, before drop forging, keeping their strength high. There are threads in the middle of the eye nut.

These threads are as per the bolt with which the eye nut is connected. The thread inside the eye nut is drilled by a bench drill machine. The thread of the eye nut has to make it easy to install.

about us

Exhibition

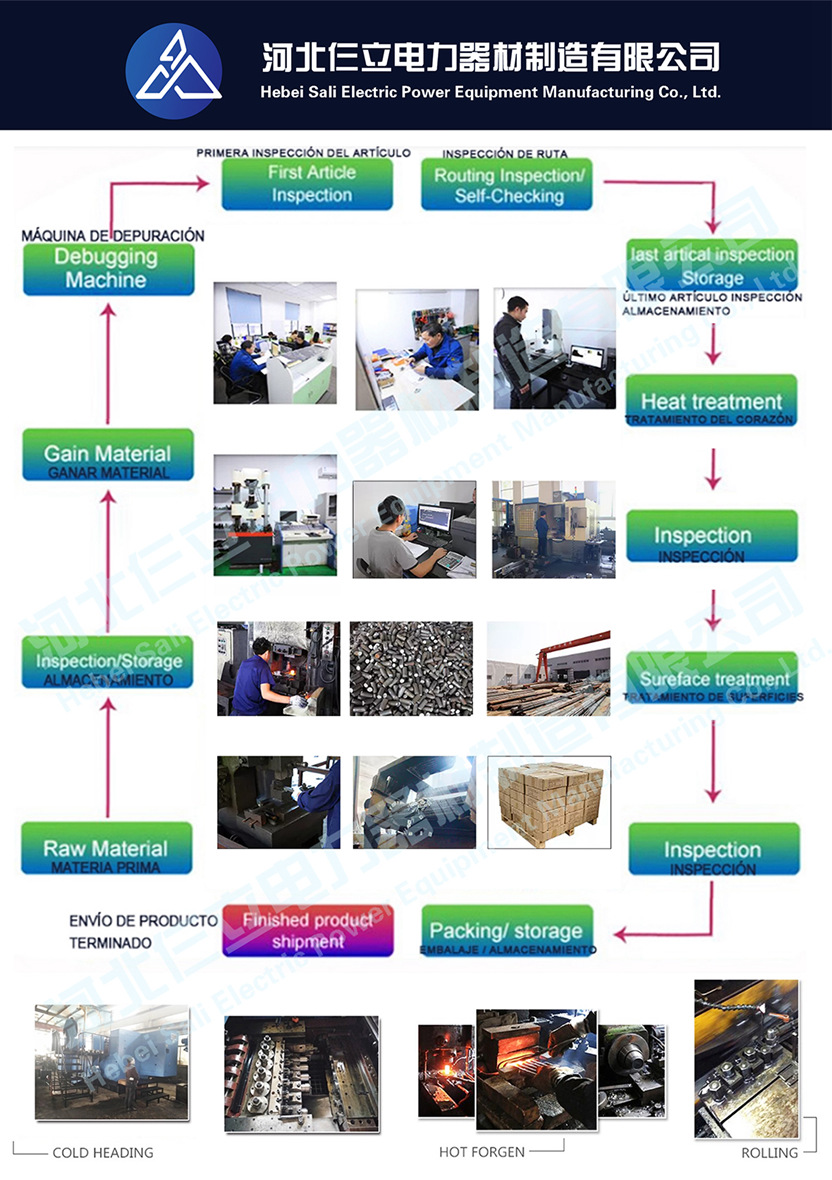

production process

Qualification certificate